Understanding Minimum Bend Radius

Share

Bend Radius & Install limitations

Understanding automotive plumbing install limitations to hose curvatures and routing.

When you go to install your new Hot Rod fuel hose plumbing you may be tempted to "just make it fit" sometimes this approach works, other times it may limit your flow or cause an increase in pressure drop which can have very negative effects on your project.

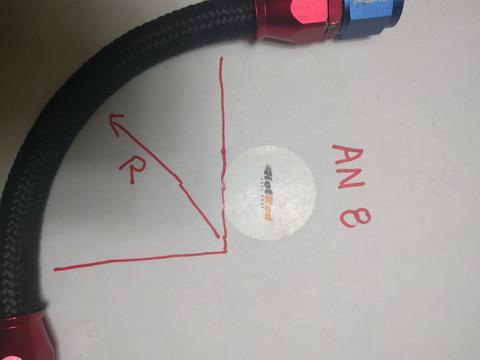

We are going to explain Bend radius today - Sometimes called Minimum bend radius. What? Minimum bend radius? I'll try to explain and then throw up a diagram so it makes more sense. When you make a curve in a hose the measurement within the curvature has a minimum distance that can be adhered too before the hose either kinks and limits flow and causes a pressure drop at the work end of your line - Usually your carb or your EFI setup OR under pressure causes extra force on the hose and you get premature wear or in high pressure situations popping the fittings right off the hose.

-R being your bend radius. In the case of our AN8 size of PTFE hose it has a minimum bend radius of 3.5 inches. So what the heck does that mean and how do I know if I am good to go? Well using the tape measure we can find that R in this case equals to about 2-3/4"

Whoops we didn't use a long enough length of PTFE hose here and went too tight for our 90 degree bend. So how do we fix it?

Now you can use math to figure out how long your length of PTFE hose needs to be for the bend to be within specs. As in how much hose where you start making the bend to where the bend finishes to be within spec for this size of PTFE lined and nylon braided hose.

Here is the nerd math.

Angle of bend / 360 X 2 π R.

90 degree bend / 360 X (2 * 3.14 * 3.5)

In this case 0.25 * 2 * 3.14 * 3.5 = ~ 5.5 inches

So we need to use 5.5 inches of hose in the PTFE hose bend itself.

Ah much better we can now sleep well at night.

Ok Ok - I know who the hell is actually going to spend time measuring out the PTFE lined and stainless or nylon braided hose. Probably nobody. In the real world when you install your hot rod plumbing use common sense if you notice an increase in resistance from the hose you are forcing it and probably exceeding the bend radius and could potentially run into trouble during your install. At the low pressures used for fuel your risks are limited to some pressure drop and reduced flow in extreme cases, but if you start running brake lines at higher pressure this becomes more important as too tight of a bend radius can pop the fittings off the hose.

Thanks for reading today - I know it was long so the first person to go to the contact page and send us a message with the correct length of hose needed for a 180 degree bend using AN6 hose will get a free gift.

Hot Rod fuel hose Minimum bend radius specs for our PTFE lined and Stainless or Nylon braided hose is as follows.

AN6 - 2.5 inches

AN8 - 3.5 inches

Happy Rodding.

Shop Now

1 comment

Great info on the bend radius! Glad you spelled out in detail how to calculate the total length of hose needed for a bend.

Can I suggest that a few other specs would be helpful: hose ID (not always exactly 1/16 * AN number), hose OD. Hose OD would be helpful for choosing the correct size Adel clamps.